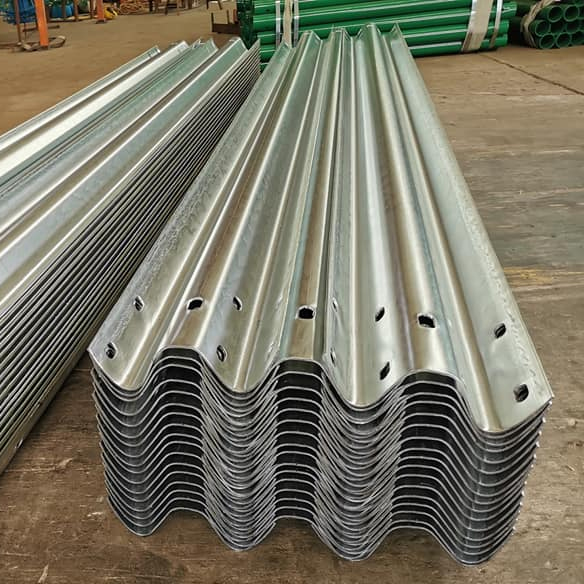

Highway Guard Rail

The name:three beam guardrail

Surface treatment:Hot Dippe Galvanized ≥550g/㎡,Powder Coated

Standard:AASHTO M180

Model: Two W beam/Thrie-beam

Capacity: 2500 pieces per day

Accept Custom Build

Three Beam Guardrail Product Description

All of our Galvanized Highway Guardrail are manufactured using Q235B/Q355B 2.65mm/3.0mm/4.0mm material.Galvanized Highway Guardrail is available in various lengths starting from 3m, 3.81m,4.13m ,4.32 and 5m lengths.Galvanised to AASHOT M180,hot-dip galvanised (zinc) coating on fabricated ferrous article,Security Highway Guardrail are made in house we also offer a custom length rail service.

The plastic spraying process of the guardrail

Work→pretreatment→hanging parts→dust spraying→curing→cooling→inspection→packaging. The requirements for plastic spraying on the surface of the workpiece are higher than those for dipping, so the guardrail must be pretreated. There are two pretreatment methods for guardrails. One is the chemical solvent method, which cleans the surface through degreasing, pickling, phosphating and other processes; the other is the mechanical method, which mainly uses jet shot blasting to remove rust. The guardrail is suspended in a horizontal manner, and each group is suspended 3 to 4 rows in parallel up and down.

There are two types of guardrail plastic spraying: cold spray and hot spray. The cold spray layer is thin and has many defects; the hot spray layer can remove moisture, increase the amount of powder, and increase the thickness of the coating, which is very beneficial to improve the service life of the guardrail outdoors.

When painting, the distance between the painting gun and the guardrail should be appropriate, generally 200mm is appropriate. Adjust the electrostatic voltage from 60 to 80 kV to make the compressed air free of oil, water and dust. Filter-type recovery device ensures that the powder does not overflow and can be recovered reasonably.

The plastic spraying process of the car guardrail.

Commonly used guardrail spray ordinary pure polyester powder coating, the curing temperature is generally 180 to 200 ℃, adjust the conveying speed, so that the guardrail can be baked continuously at this temperature for 20 to 25 days. For the column, due to the thick wall of the column, the baking time should also be extended appropriately.

Three Beam Guardrail Application

Three Beam Guardrail Shipping and Export