Highway Guardrail Systems

Size :4320*310*85 (custom accepted)

Thickness:3mm

Zinc Coating:≥550g/㎡ (both sides)

Raw Material:S235JR(Q235B)

Techinical Treatment:Hot dipped galvanized

Package Method:Package 20 pcs into bundles

Payment Terms:TT,L/C,D/P etc.(Negotiating)

Delivery Time:15-20 working days

Shipping Mode:by sea or by train

Product Description

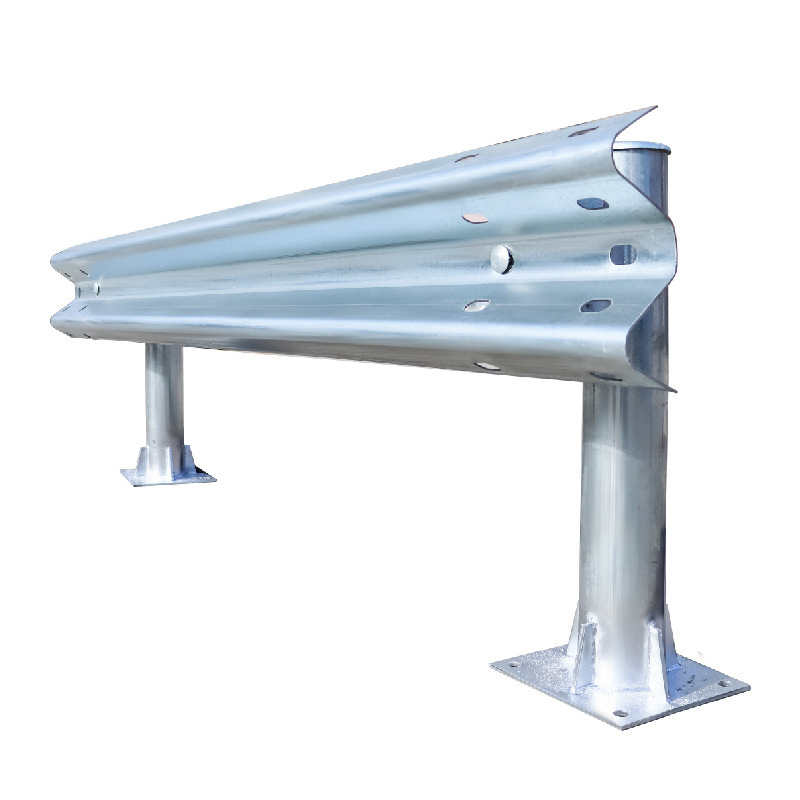

Highway Guardrail Systems is a longitudinal, roadside barrier system that is installed to prevent errant vehicles from impacting roadside obstacles. By redirecting a vehicle departing the roadway, a guardrail keeps it away from more serious hazards, both constructed (e.g., sign structures, culvert inlets, utility poles) and natural (e.g., trees, rock outcrop). Guardrail prevents vehicles from descending a steep roadside embankment or veering into the roadway median and oncoming traffic. In some cases,Highway Guardrail Systems is installed for reasons other than to safeguard motorists against obstacles (e.g., road closure barricades and barriers protecting pedestrians or sensitive areas).

The Specification

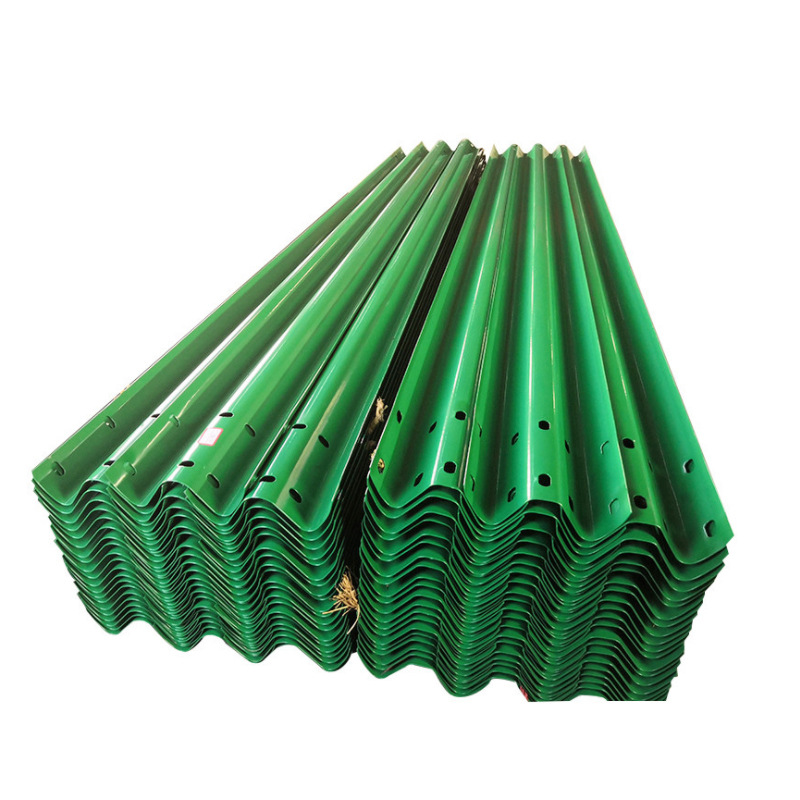

Sizes | 4320*310*85*3mm |

Materail | S235JR |

Profile | |

Surfacce treatment | Hot Dipped Galvanized |

Applicabele Standards | JT/T2811995(Corrugated Sheet Steel Beams For Expressway Guardrail - China), AASHTO M180(Corrugated Sheet Steel Beams For Highway Guardrail - USA), RAL RG620 (German) or any other International Standards |

Base Steel | Grade Q235B (equivalent to S235JR according to DIN EN 10025 and Gr. Daccording to ASTM A283M) or Q355 (S355JR / ASTM A529M 1994) |

The Thickness of Galvanized (Double Sides) | 550g/m2 (40µ) or 1100 g/m2 (80µ) or 1200 g/m2 (85µ) or as per your request |

Features | Great corrosion resistant, high intensity, long and durable, with good impact resistance, low cost, long life, higher |

Relevant Parts | Required for Guardrails Post, Spacer (C, U and Sigma types etc) and Fasteners, Bolts&Nuts,Terminal,Reflectors etc. |

MOQ | one 20 FT container or negotiate |

Price Terms | FOB,CFR,CIF etc. |

Payment Terms | T/T,L/C at sight etc. |

Other special specification as per client's requirement or drawings | |

Success Case

Production Flow

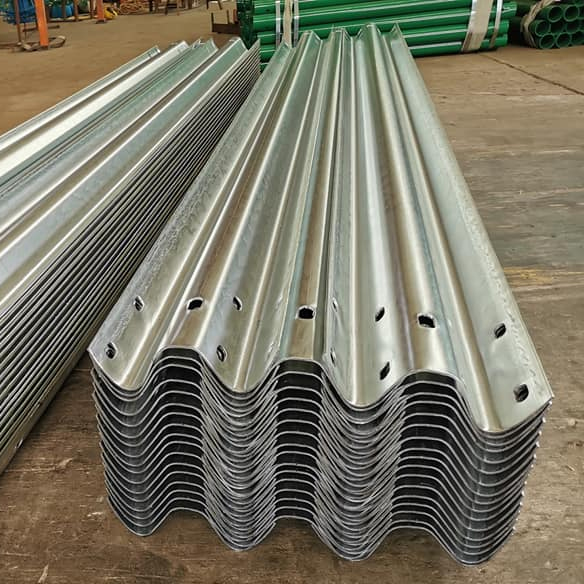

Process differences Hot-dip galvanizing process: pickling of products - cleaning - adding auxiliary plating solution - drying - hot-dip galvanizing - cooling - passivation - cleaning - grinding - hot-dip galvanizing completion. The hot-dip zinc layer is formed by zinc in liquid state in three processes. The surface of the iron base is dissolved by the zinc liquid to form a zinc-iron alloy phase layer; the zinc ions in the alloy layer further disperse to the substrate to form a zinc-iron mutual-soluble layer; the alloy layer The surface is covered with zinc layer.

Shipping and Export Show

Our Advantages

1. A professional manufacturer and supplier of safety and protection products;

2. The company has many years of export experience and the export share is about 50%

3. Designing, developing and customizing products according to customers' requirements

4. Provide one-to-one online installation guidance