Traffic Barriers

The name:Traffic Barriers

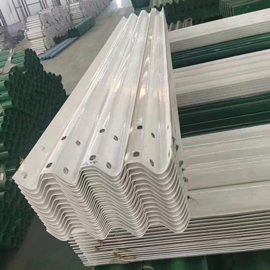

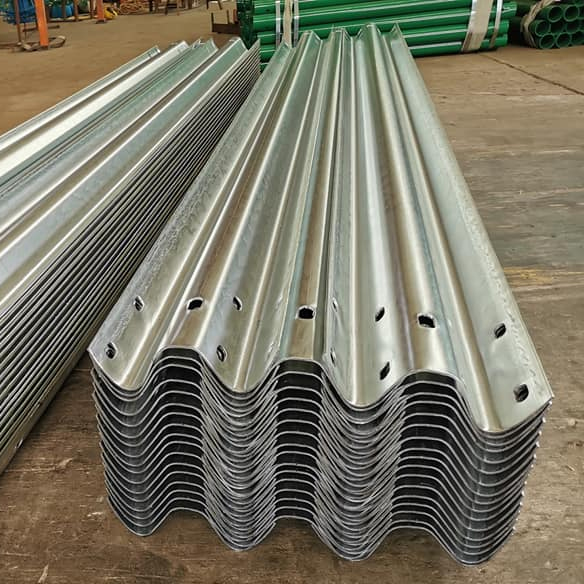

Surface treatment:Hot Dippe Galvanized ≥550g/㎡,Powder Coated

Standard:AASHTO M180

Model: Two W beam/Thrie-beam

Capacity: 2500 pieces per day

Accept Custom Build

Three Beam Guardrail Product Description

Traffic Barriers are manufactured using Q235B/Q355B 2.65mm/3.0mm/4.0mm material.Galvanized Traffic Barriers is available in various lengths starting from 3m, 3.81m,4.13m ,4.32 and 5m lengths.Galvanised to AASHOT M180,hot-dip galvanised (zinc) coating on fabricated ferrous article,Security Highway Guardrail are made in house we also offer a custom length rail service.

Guardrail production process

1. In order to ensure the production process of high-speed guardrail panels, the most important thing is to select materials strictly in accordance with the specific requirements of standards or contracts. The selected materials are mainly column steel pipes, galvanized metal plates, etc.

2. Before production, we need to draw drawings according to the actual situation to determine the height of the guardrail and the distance between the wave crests. This information must be as accurate as possible, otherwise the quality of the high-speed guardrail production process cannot be guaranteed.

3. Next, we need to adjust the guardrail panel production equipment according to the data, and then place the galvanized steel plate on the production equipment and extrude it to make a corrugated guardrail panel that meets the requirements.

4. Then drill holes in the formed guardrail. The production process of high-speed guardrail panels requires that the hole spacing should be as precise as possible. Otherwise, it will happen that the bolt cannot be fixed when it is installed. The hole diameter should be as large as possible, so that it is more flexible and convenient to install.

5. The next step is the anti-corrosion treatment of the high-speed guardrail. The anti-corrosion treatment methods commonly used in the production process of the high-speed guardrail are mainly galvanizing, soaking, and galvanizing and dipping. The anti-corrosion treated high-speed guardrail must be dry, especially the sprayed plastics such as dipping and anti-corrosion treatment are completely attached and solidified on it before they can be packaged.

6. At this point, the production process of the high-speed guardrail is almost completed, and the packaging can be carried out below. Packaging is very important, because collisions are inevitable during transportation, and damage to the skin coating of the product will affect the lifespan.

Three Beam Guardrail Shipping and Export