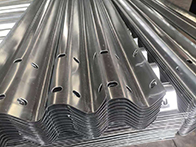

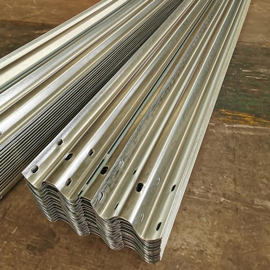

Corrugated Steel Guardrail

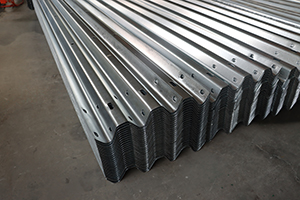

Raw material: national standard Q235, low-carbon steel plate, etc.;

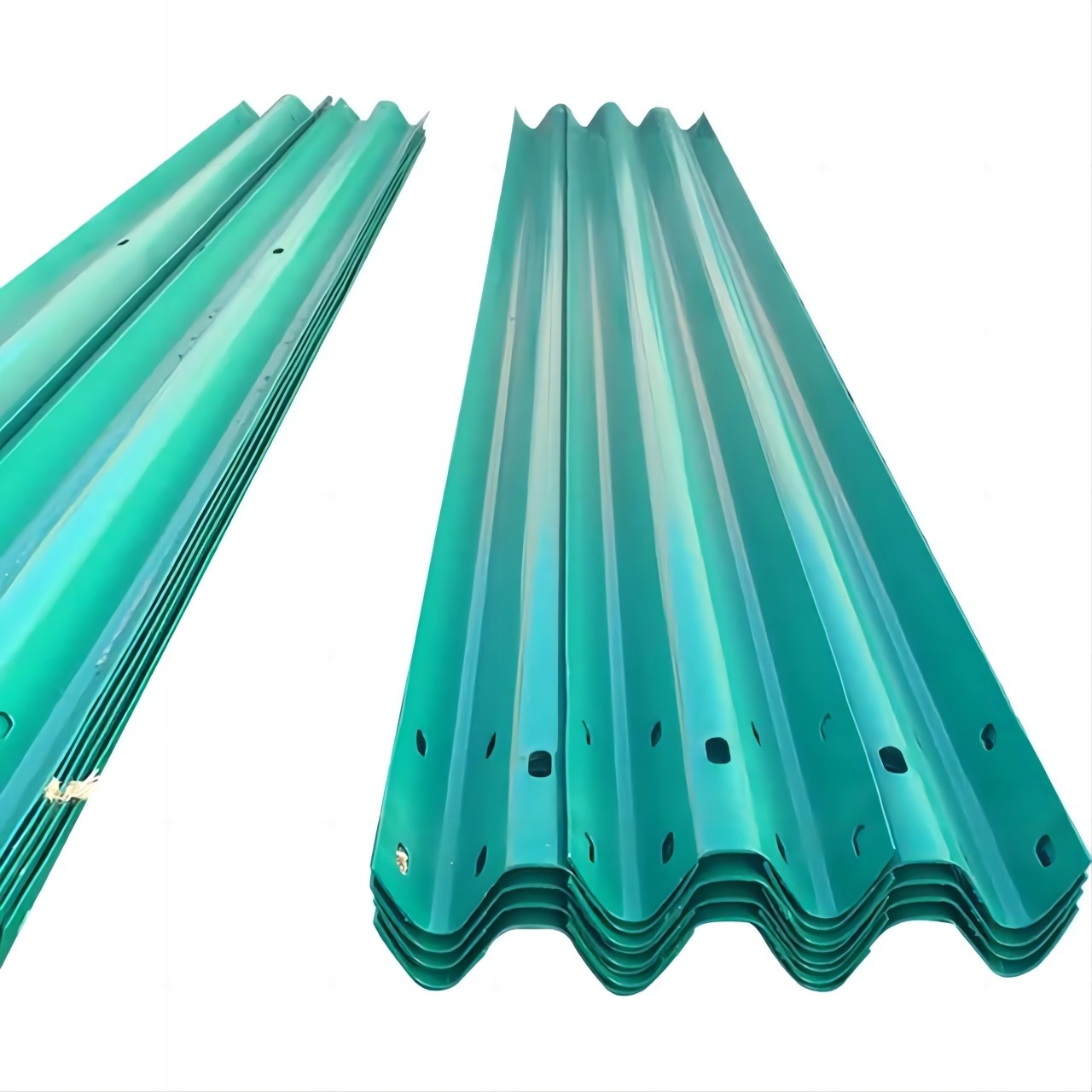

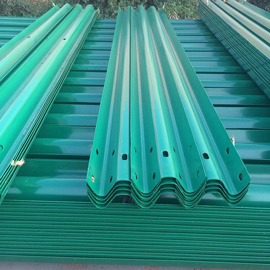

Surface treatment method: plastic dipping after extrusion; electro-galvanized/hot-dip galvanized steel sheet can also be dipped or sprayed after stamping;

low-carbon steel blackboard is dipped after extrusion; low carbon Steel blackboard is extruded and galvanized + plastic dipping/spraying; plastic dipping material is (pvc&pe);

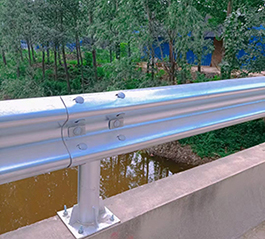

scope of application: safe collision avoidance for highways, large parking lots, etc.; product features: bending increases aesthetics and increases the strength of the mesh , kill two birds with one stone; Extruded by automated production line, the surface is clean and non-destructive, strong anti-corrosion; surface treatment method is mature; PE&PVC material has the characteristics of non-toxic, harmless, anti-corrosion, anti-aging, corrosion-resistant sunlight, high temperature resistance, low temperature resistance, etc., in outdoor environment The service life can reach 10-20 years; the product structure is simple, beautiful and practical, convenient for transportation and installation, and has good anti-theft performance. Limited by the actual terrain, it is suitable for mountains, slopes, and multi-bend areas. It has strong adaptability and moderate cost. It is suitable for large scale adoption.

Product description

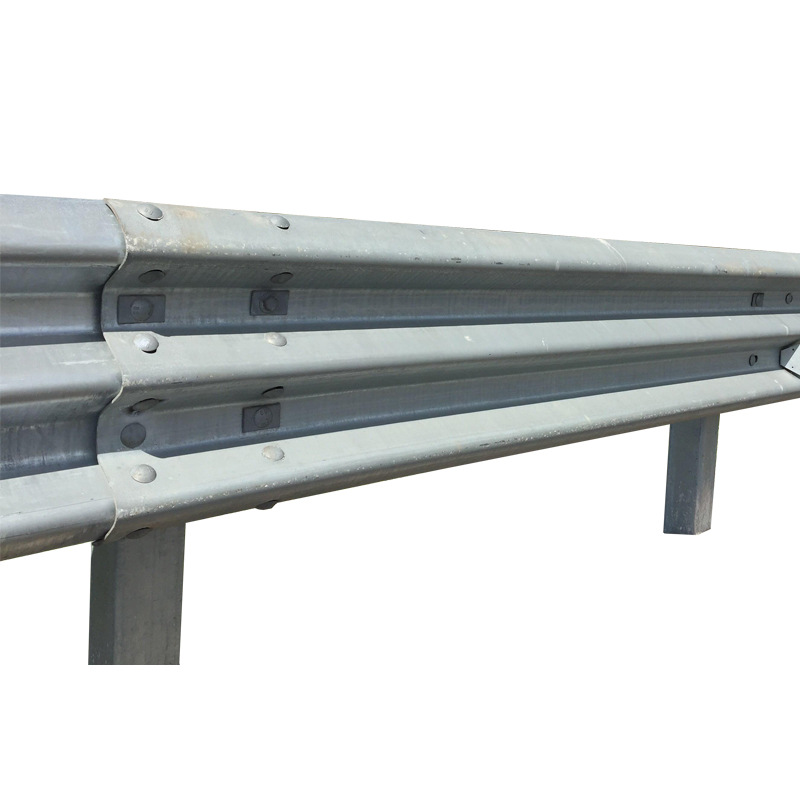

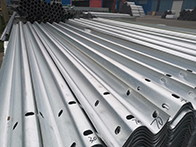

Galvanized highway guardrail, a continuous structure of corrugated steel guardrails spliced together and supported by main posts. In the vehicle collision on its role in absorbing energy is not easy to be destroyed, but also to protect the vehicle and passengers. Often referred to as "highway guardrail / W-beam / collision guardrail / guardrail / traffic guardrail / highway guardrail / high-speed guardrail / industrial guardrail / traffic guardrail / post / guardrail".

Reasons for Corrugated Steel Guardrail

Corrugated Steel Guardrail uses the deformation of the soil foundation, columns, and beams to absorb the collision energy, and force the out-of-control vehicle to change direction and return to the normal driving direction, preventing the vehicle from rushing out of the road, so as to protect the vehicle and passengers and reduce accidents caused losses.

The main reasons for the peeling off of the zinc layer on the hot-dip galvanized surface are as follows:

1. The aluminum content in the steel alloy layer of the guardrail plate is low, and no reasonable alloy layer that plays a decisive role in the adhesion of the zinc layer is formed, or the alloy layer is damaged by the excessively grown iron-zinc alloy layer.

2. There is an iron oxide layer on the surface of Corrugated Steel Guardrail. In the annealing furnace, the substrate is not completely reduced to the spongy pure iron required for galvanizing, which can also cause the zinc layer to fall off.

3. When the surface of Corrugated Steel Guardrail is galvanized, the impurity particles remain, and they are not removed when they invade the zinc pot, thus affecting the zinc.

Our Advantages

1. Specialized manufacturer and supplier of safety and protection products;

2. The company has many years of experience in exporting, and the export share is about 50%;

3. Design, development and customization of products according to customer requirements;

4. Provide one-to-one online installation guidance and 24-hour service hotline.