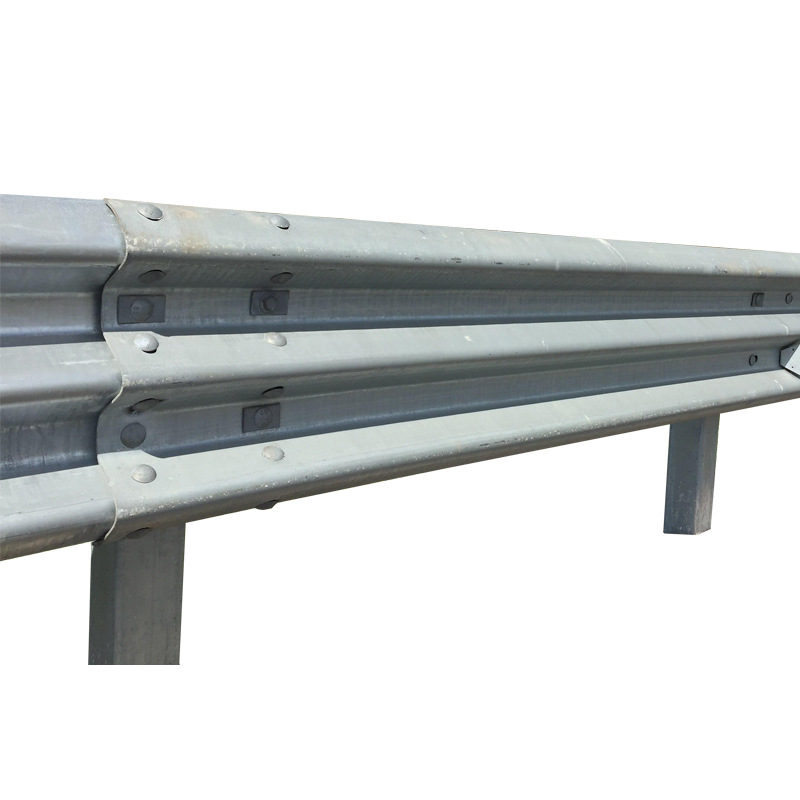

High Quality Highway Guardrail

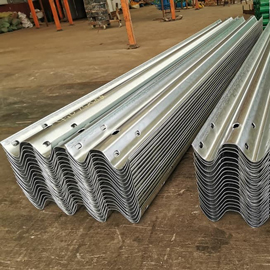

When the vehicle crashes, the corrugated guardrail plate has good crashworthiness and energy absorption effect, it is not easy to be damaged, and has a good protection effect with the vehicle and passengers. The corrugated guardrail plate has the advantages of good impact resistance, low cost, long life, high safety and green environmental protection. Therefore, more than half of the widely used high-speed anti-collision facilities use waveform guardrails.

W Beam guardrail Weight

4320mm*310mm*85mm*3; Weight: 49.16KG

4320mm*310mm*85mm*4; Weight: 65.55KG

Product Description

High Quality Highway Guardrail is a facility used to protect the safety of vehicles and personnel on traffic roads, commonly known as w-beam guardrail, highway guardrail, steel road barrier, etc. One of the functions of High Quality Highway Guardrail is to absorb the kinetic energy of the vehicle to reduce the damage caused by a collision, and it is often used in dangerous roads.The size and model of High Quality Highway Guardrail can be customized, if you want to know more, please contact us.

Length | 3810mm-4320mm or Customized |

Material | Q235/Q345 |

Color | Customized |

Feature | Anti-corrosion |

Thickness | 2.5mm-4mm or Customized |

Technology

Hot-dip galvanizing

All parts of highway anti-collision guardrail generally adopt hot-dip galvanizing for metal surface treatment, in order to ensure its anti-corrosion performance, it is necessary to test from the three aspects of the adhesion amount of galvanizing layer, the uniformity of galvanizing layer and the adhesion performance of galvanizing layer.

(1) Adhesion of galvanized layer The adhesion test of galvanized layer adopts the hammer method. The specimen is placed horizontally, the hammer head is facing the center of the bench, the hammer handle is perpendicular to the plane of the base and then falls freely, and the five points are struck in parallel at a 4mm interval. The adhesion of the specimen is judged by checking the surface state of the zinc layer and whether the zinc layer is peeling and convex.

(2) Material properties test The properties of steel mainly refer to mechanical properties, which can be divided into strength properties, plasticity and impact toughness. Strength performance indicates the resistance of steel to plastic deformation and damage, including elastic limit, yield limit, strength limit, fatigue limit and hardness. Plasticity indicates the plastic deformation capacity of steel, including elongation. Area reduction and cold bending. Impact toughness indicates the resistance of steel to impact loads. Because the content of various components in the material affects the mechanical properties of the steel, the test of the raw material properties of the steel plate includes chemical analysis, tensile test and bending test.

Packaging & Delivery

Standard export packing

FAQ

Q1: What's the terms of delivery?

A: EXW, FOB, CFR, CIF

Q2: What's the terms of packing?

A: Generally,we pack our goods in bundles or coils with rods or belts, we could also pack the goods as the customers' requirement.

Q3: Could you produce according to the samples?

A: Yes, we can customer-made by your samples or technique drawings, we can build the mold and fixtures.